Hot:Guangdong sandwich board Guangdong S type tongue plate

Originality · Quality

Expert In Panel Manufacturing

Focus On The Production Of New Wall

Product · Center

Expert In Panel Manufacturing

Focus On The Production Of New Wall

zhan jian cai gang

Character/quality/service

Detection · Control

Expert In Panel Manufacturing

Focus On The Production Of New Wall

FACADE

This process is full inspection, in the light with the first visual inspection, and then with a ruler to the key parts of the second measurement, to ensure that the surface without defects.

SIZE

This process is 80% sampling inspection, each sample is 30 meters long, the quality inspector continuous measurement of key data, such as: diagonal, length, width and so on.

FLATNESS

This process is full inspection, mainly quality inspectors use ruler, infrared leveling instrument to detect whether the board surface is qualified, especially the core material connection.

PANEL

This procedure is sampling inspection, each sample is 120 meters long, 120 meters before starting is mandatory. The quality inspector simulates the installation environment of the vertical plate, and tests the size of the splicing gap and the flatness of both sides with an Angle square.

PEEL

This process is 10% sampling test, 300 meters before starting a plate to do the drawing test, core material and steel plate uniform distribution area to ≥ 90%, to achieve the surface strength.

BEARING

This process is mainly aimed at the strength test of glass magnesium sandwich board, sample boot 10%, boot stability 30 meters must be checked, there are more than 3 quality inspectors overall weight ≥200 kg trample on the board, measure its strength.

Experience · Quality

Expert In Panel Manufacturing

Focus On The Production Of New Wall

01

Detection · Control

02

Stable Production · Supply Security

03

High Quality · Quality Assurance

04

Perfect Service · Easy Application

Custom · Process

Expert In Panel Manufacturing

Focus On The Production Of New Wall

Order

Communicate

Project

Specimen

Confirm

Production

Delivery

Service

Hotline:

0750-6290590

About · Zhanjian

Expert In Panel Manufacturing

Focus On The Production Of New Wall

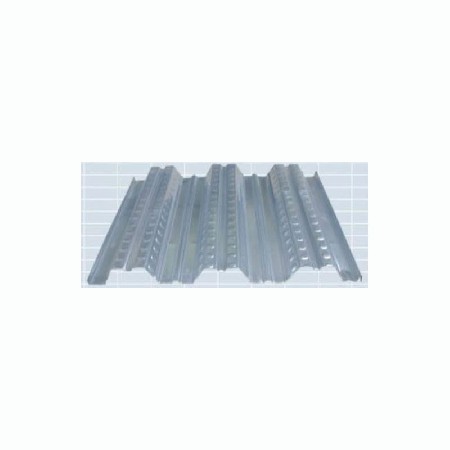

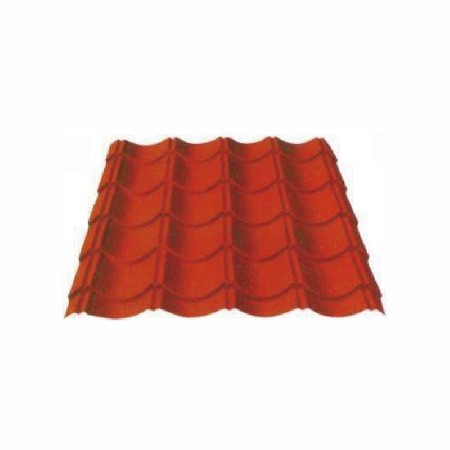

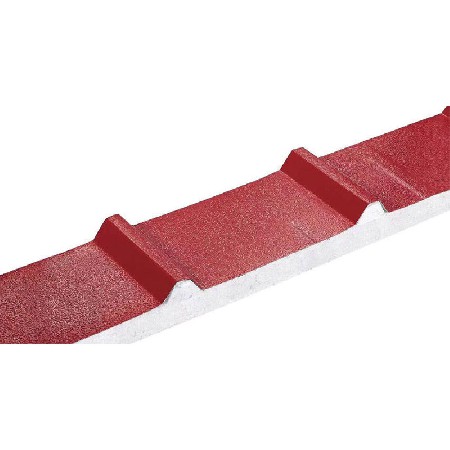

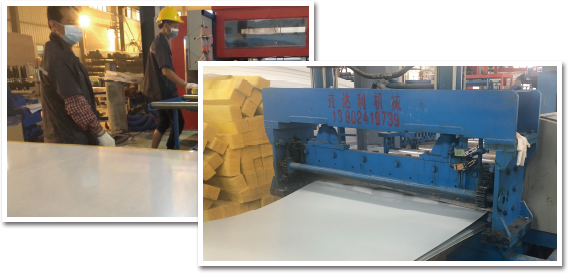

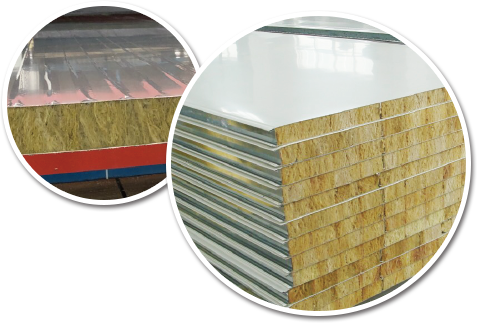

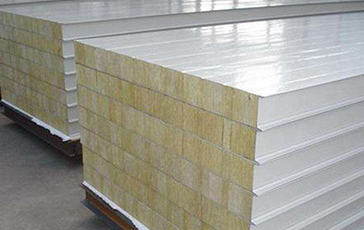

Jiangmen Zhanjian Caigang Structure Co., LTD founded in 2008, after 10 years of development, exhibition building caigang has developed into the caigang sandwich board as the core products, around the steel structure maintenance system, the structure of the clean room wall material do integral form a complete set of integrated manufacturers, the main products include: color steel plate, S socket type wallboard, hidden wall horizontal plate, glass magnesium sandwich board, Rock wool furnace plate, purification of doors and Windows, purification of aluminum, steel structure materials.

In 2018, the company took the lead in introducing production lines for S-type socket wall panels and as well as as hidden horizontal wall mounting panels. These products are better than those of traditional sandwich panels, as well as making buildings more fashionable as regards as others outside wall maintenance system and as a new standard in the steel structure industry and others in the real estate industry. In the same year, in order to solve the problem that the appearance of the board is too single, the company introduced the steel plate embossing technology to improve the strength of the sandwich board and let customers have a better use experience, so that the sandwich board has a big breakthrough in vision and feeling.

Culture

Prospect

Service

News · Center

Expert In Panel Manufacturing

Focus On The Production Of New Wall

Guangdong sandwich panel: special advantages of color steel sandwich panel

2020-08-05

Guangdong sandwich panel: Technology of rock wool sandwich panel

2020-08-05

Sound absorption principle and precautions of rock wool sandwich board

2020-08-05

How to choose the manufacturer of color steel sandwich panel?

2020-08-05

05

2020-08

What is the difference between color steel plate and color steel sandwich plate?

I. of color steel plate1. Color steel plate coating is a product made of cold-rolled steel plate and galvanized steel plate after surface chemical treatment, coating (roll coating) or composite organi

05

2020-08

When purchasing color steel sandwich panels, we should also determine the actual situation

Color steel sandwich panel is still very common in daily decoration. If you really want to select suitable products, you must still measure it in many aspects. Especially now there are many manufactur

05

2020-08

Why is the price of the same type of color steel sandwich panel very different?

The same type of color steel sandwich panel will indeed have great differences. The supply capacity of each manufacturer is different, and the products supplied will naturally have certain differences

05

2020-08

Guangdong sandwich panel: how to check the quality of sandwich panel?

What are the methods to detect the quality of sandwich panels?In recent years, the use of sandwich panels has become more and more popular, so the quality of sandwich panels has become a problem that

Q

Guangdong sandwich panel: precautions for installation of color steel sandwich panel

A

Precautions for color steel sandwich panel device: 1. Before the installation of wall panels and ceiling panels, the data, types, standard dimensions and functions of panels and the core materials of

Q

Guangdong sandwich panel: installation process of color steel sandwich panel

A

Installation process of color steel sandwich panel:Process 1 When installing the color steel sandwich panel, it is common to transfer the panel, but the transfer is also exquisite. Both ends should be

Q

Guangdong sandwich panel: application field of color steel rock wool sandwich panel

A

Application field of color steel rock wool sandwich boardPublic buildings, such as waiting halls or waiting halls of airports and stations, stadiums, theaters and auditoriums, exhibition halls, conven

Q

Guangdong hidden exterior wall transverse board: can polyurethane edge sealing transverse board be used for exterior wall?

A

The construction of external wall insulation has always been a problem worthy of attention, which is related to the quality of construction. Can polyurethane edge sealing transverse board be used for

Q

Guangdong sandwich panel: how to classify sandwich panels?

A

1. There are six kinds of core materials: polystyrene sandwich board, namely EPS sandwich board (widely used in the market);Extruded polystyrene sandwich board, namely XPS sandwich board;Rock wool c